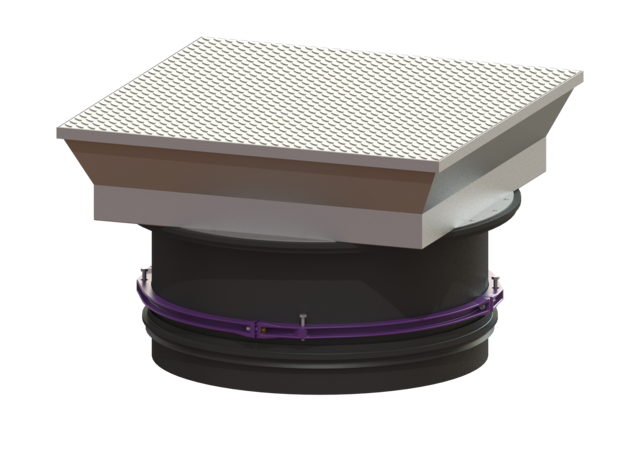

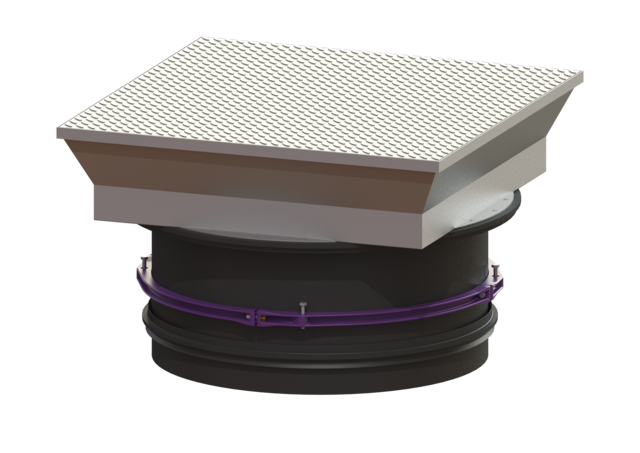

Backwater lifting station Ecolift XL

Duo, 1 motor-driven flap, SPF 1500-S3, Taper

The backwater lifting station for non-faecal wastewater is equipped with two submersible pumps, one motor-driven and one mechanical closure system and a backflow preventer. The collection tank made of permanently resistant polymer (PE) has an enclosed pump tank. Quick-release closures enable the integrated components to be removed easily. Normally, draining takes place via the natural fall to the sewer. Backwater is detected by an optical probe, which causes the motor-driven closure system to close automatically and there is no longer free passage to the sewer. During the backwater phase, the water drains via a pressure pipe, which carries the wastewater into the sewer. The pressure pipe is a welded PE pipe; with pump SPF 4500, the pressure pipe must also be continued up to a pressure release chamber. The station is controlled by a user-friendly control unit, which is optionally integrated in the building management system via a potential-free contact, or alarm and collective fault messages can be output via a GSM interface. The KESSEL modular system provides different upper sections and engineering chamber options as accessories.

- Wastewater drainage without interruption, even if a power failure occurs

- Low pump use

- minimised noise emissions

- ensures low power consumption

- Reduced maintenance costs due to longer maintenance intervals in commercial/industrial use

| Item no. | 8741061 |

|---|---|

| GTIN | 4026092070703 |

| Price group | 60 |

Backwater lifting station Ecolift XL Duo, 1 motor-driven flap, SPF 1500-S3, Taper

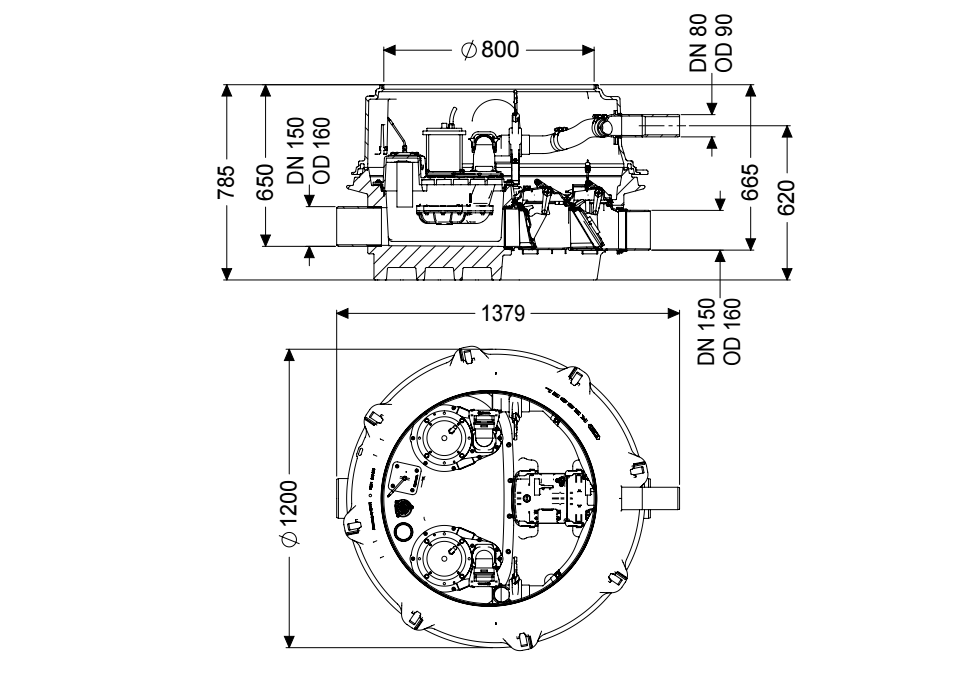

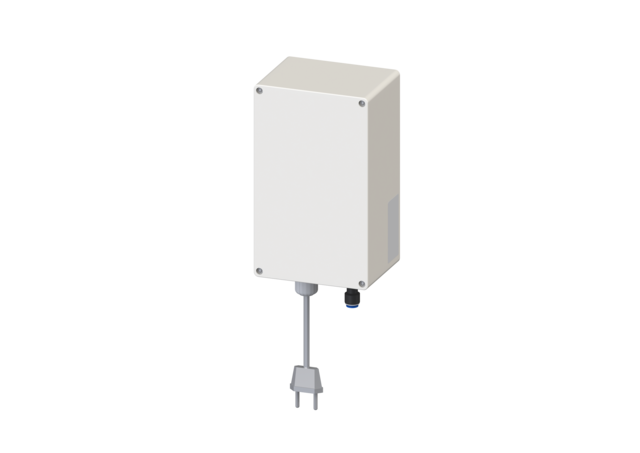

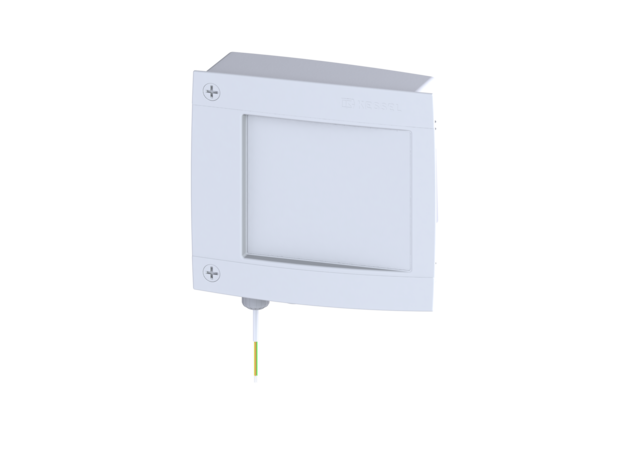

The backwater lifting station for non-faecal wastewater is equipped with two submersible pumps, one motor-driven and one mechanical closure system and a backflow preventer. The collection tank made of permanently resistant polymer (PE) has an enclosed pump tank. Quick-release closures enable the integrated components to be removed easily. Normally, draining takes place via the natural fall to the sewer. Backwater is detected by an optical probe, which causes the motor-driven closure system to close automatically and there is no longer free passage to the sewer. During the backwater phase, the water drains via a pressure pipe, which carries the wastewater into the sewer. The pressure pipe is a welded PE pipe; with pump SPF 4500, the pressure pipe must also be continued up to a pressure release chamber. The station is controlled by a user-friendly control unit, which is optionally integrated in the building management system via a potential-free contact, or alarm and collective fault messages can be output via a GSM interface. The KESSEL modular system provides different upper sections and engineering chamber options as accessories. Type of wastewater: wastewater without sewage Installation situation: underground installation, floor slab installation Version: Type of system: Twin pump station Shut-off valve: Shut-off valve made of polymer Pump control: Control unit Backflow preventer: integrated Note on installation depth: Version with lowest installation height Passage seal for ventilation pipe (DN): 70 mm Passage seal for conduit pipe (DN): 100 mm Delivery state: Pre-mounted for final assembly on site (pumps and sensor system must be fitted on site and control unit must be connected) Backwater protection: Type 3 Number of mechanical backwater flaps: 1 Number of motor-driven backwater flaps: 1 General characteristics: Colour: black Approval: Z-53.2-493 Dimensions: Length: 1,245 mm Width: 1,200 mm Height: 780 mm Tank: Number of inlets: 1 ST Inlet nominal size (DN): 150 Number of outlets: 1 ST Outlet nominal size (DN): 150 Distance pipe bottom inlet to tank bottom: 135 mm Distance pipe bottom outlet to tank bottom: 120 mm Tank volume: 65 l Pumping volume: 20 l Pressure pipe connection: horizontal Pressure pipe connection (DN): 80 mm Pressure pipe connection (OD): 90 mm Venting connection (DN): 70 mm Channel: continuous channel Groundwater resistant from lower edge of base section: 3,000 mm Clear width of tank (LW): 1,000 mm Clear width of entry (LW): 800 mm Nominal pressure (PN): 10 Free passage: 40 mm Pumping device: Pump: SPF 1500 Number of pumps: 2 Max. pumping capacity: 28 m3/h Max. pumping height: 7.5 m Operating mode: S3 - 50 % Power P1: 1.4 kW Power P2: 1.1 kW Speed: 1,415 U/min Type of fuse required (electrical protection): 3 x C 16 A Max. temperature (permanent) of conveyed material: 40 °C Connection type: Direct connection Weight: 24 kg Impeller type: Multi-vane impeller Length of mains cable for pump: 10 m Rated current: 2.7 A Protection class (pump): IP 68 (3m/48h) Protection class: I Type of pump connection cable: H07RN-F 7G 1.5 mm2 Temperature monitoring: integrated Cos phi - power factor: 0.77 Insulation class: F Vertical drop between inlet and outlet: 15 mm Control: Control unit: Comfort Plus Operating voltage: 400 V Mains frequency: 50 Hz Self-diagnosis system (SDS): yes Battery buffering: yes Multi-line display: yes Log book function: yes USB interface: yes GSM interface: yes Potential-free contact: yes Motor protection switch: yes Standby power: 5 W Protection class control unit: IP 54 Length of mains cable for control unit: 0 m Type of level measurement: pneumatic Level measurement instrument: Immersion pipe Alarm sensor: optical probe

Installation Video

| Title | Item no. | ||

|---|---|---|---|

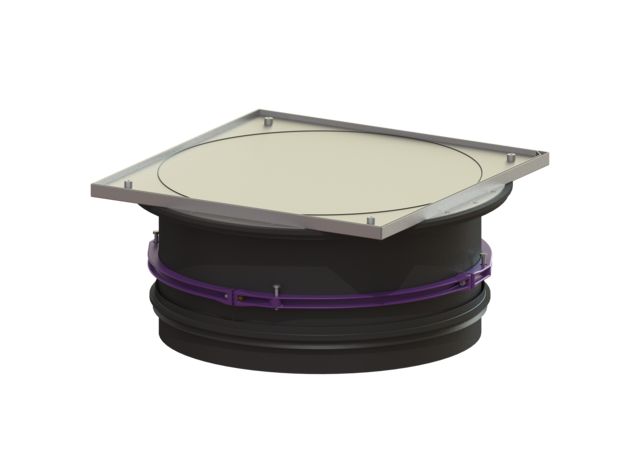

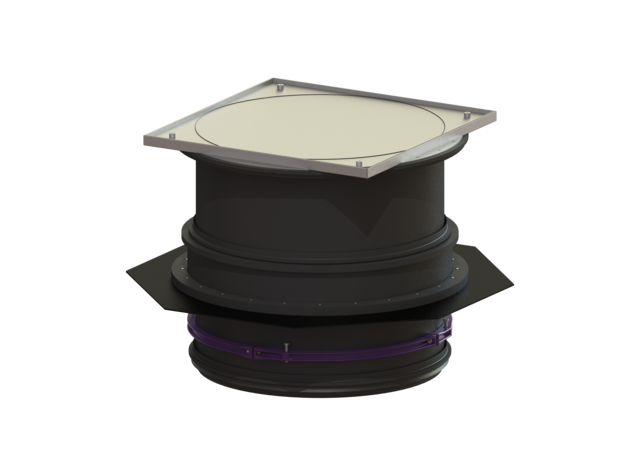

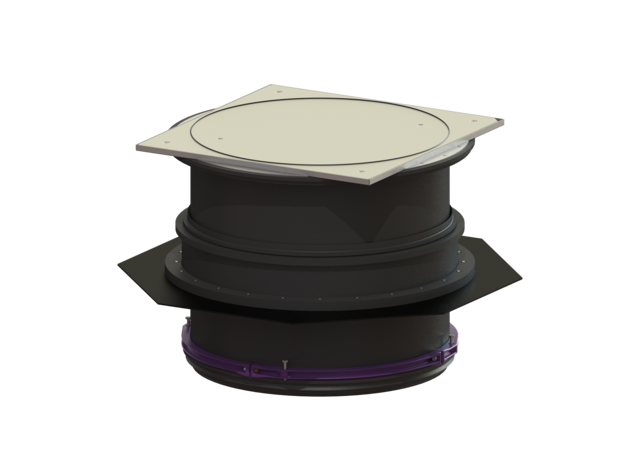

| Upper section with cover plate LW 800, Class K 3, tileable | 8740175 | Show |

| Upper section with cover plate LW 800, Class K 3 with waterproof flange | 8740176 | Show |

| Upper section with cover plate LW 800, Class A/L15 | 8740177 | Show |

| Upper section with cover plate LW 800, Cl. A/L15 with waterproof flange | 8740178 | Show |

| Upper section with cover plate LW 800, Class B | 8740179 | Show |

| Upper section with rectangular cover plate LW 800, Class D | 8740180 | Show |

| Upper section with cover plate LW 800, Class K 3 | 8740181 | Show |

| Title | Item no. |

|---|

| Title | Item no. | ||

|---|---|---|---|

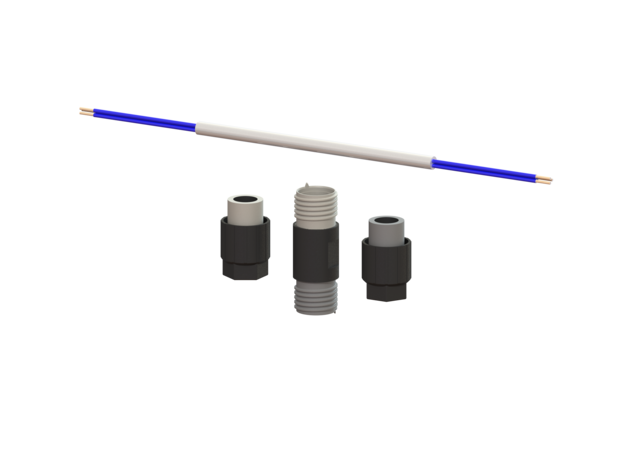

| Remote signal generator 20 m cable, 2x0.75 q | 20162 | Show |

| Compressor set for air bubbling | 28048 | Show |

| TeleControl GSM modem for Comfort control units 230V/400V | 28792 | Show |

| 10 m probe cable extension set | 80889 | Show |

| Cable extension set for motor 10 m | 80890 | Show |

| Cable prolongation set for pump 10 m | 80891 | Show |

| Installation set Thermostat, Hygrostat | 97713 | Show |

| Outdoor control cabinet W: 590 mm, for control unit installation | 97714 | Show |

| Warning beacon for outdoor control cabinet | 97715 | Show |

| Outdoor control cabinet W: 460 mm, for control unit installation | 97716 | Show |

| Outdoor control cabinet W: 785 mm, for control unit installation | 97723 | Show | |

| Outdoor control cabinet W: 1115 mm, for control unit installation | 97724 | Show |

| Title | Item no. | ||

|---|---|---|---|

| Splash guard set for optical probe | 28706 | Show |

| Comfort Plus control unit 400V 2,5-4,0A | 28786 | Show |

| Battery 9 V block | 680034 | Show |

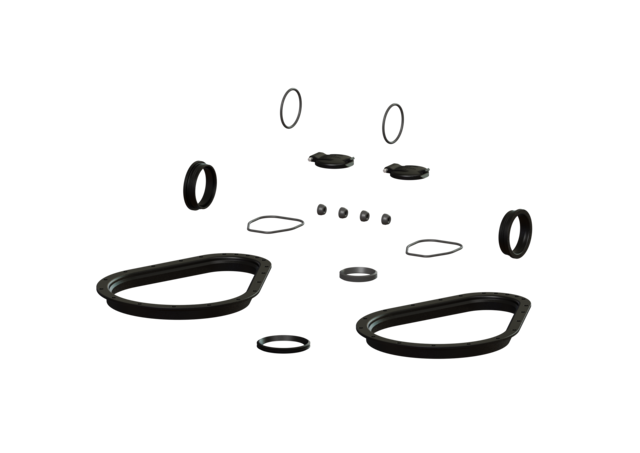

| Seal for SPF 1400 - SPF 4500 | 680052 | Show |

| Pressure hose Sold by the metre, 6x4 mm 100 | 680071 | Show |

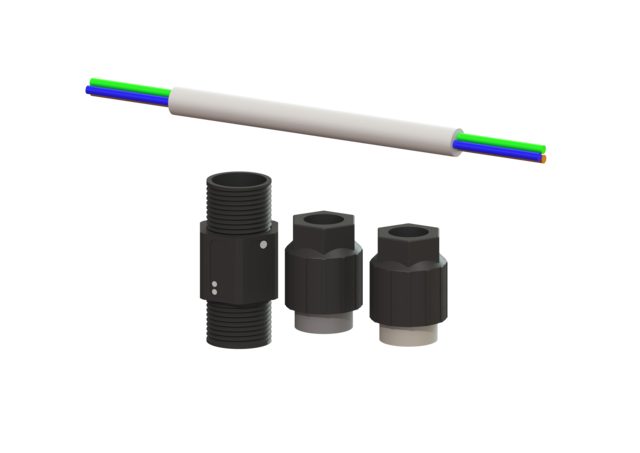

| Pump drive SPF 1500 400 V, S3, 10 m cable | 680098 | Show |

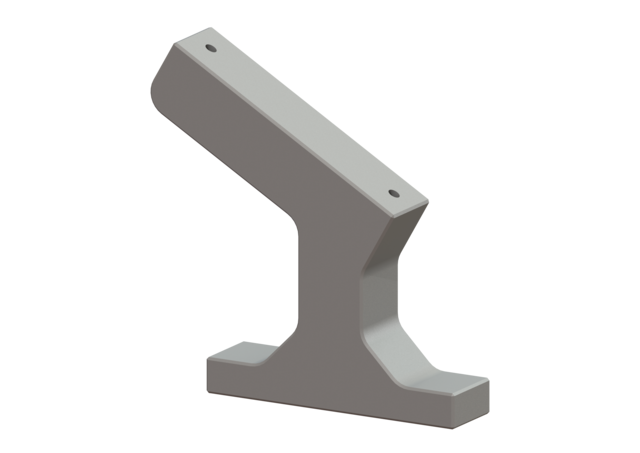

| Flap holder for motor-driven and mechanical flap | 680101 | Show |

| One-handed closure DN 63 | 680380 | Show |

| Backflow preventer left, with non-return flap | 680381 | Show |

| Backflow preventer right, with non-return flap | 680382 | Show |

| Valve key for shut-off valve DN 63 | 680386 | Show |

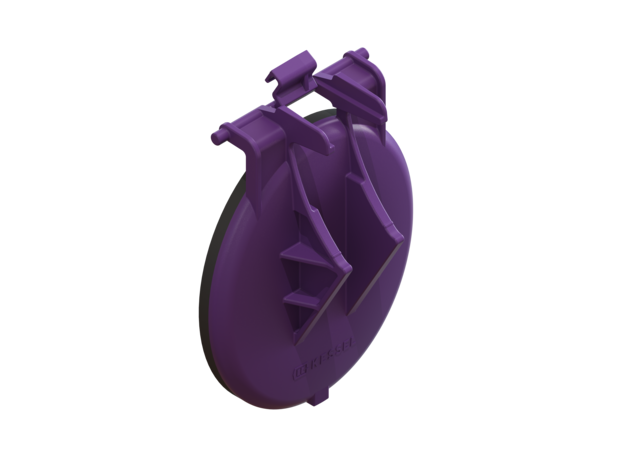

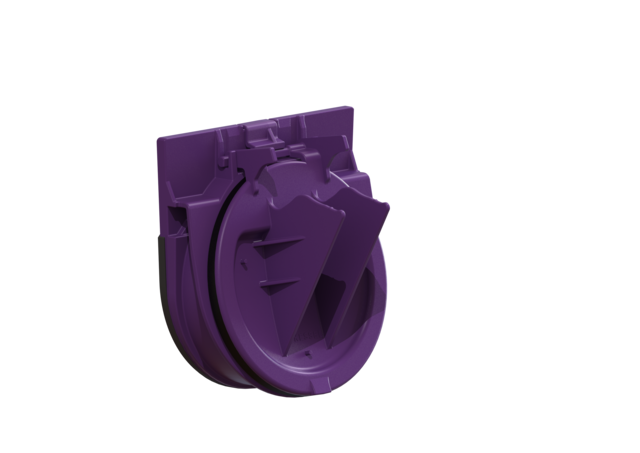

| Ecolift XL lockable cover Outlet side | 680391 | Show |

| Pump flange Ecolift XL, incl. seal | 680398 | Show |

| Pump plate Ecolift XL | 680399 | Show |

| Pressure hose DN 63, L: 367 mm | 680400 | Show |

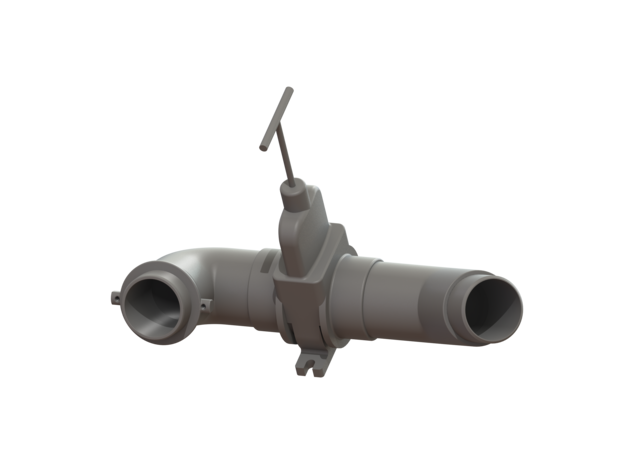

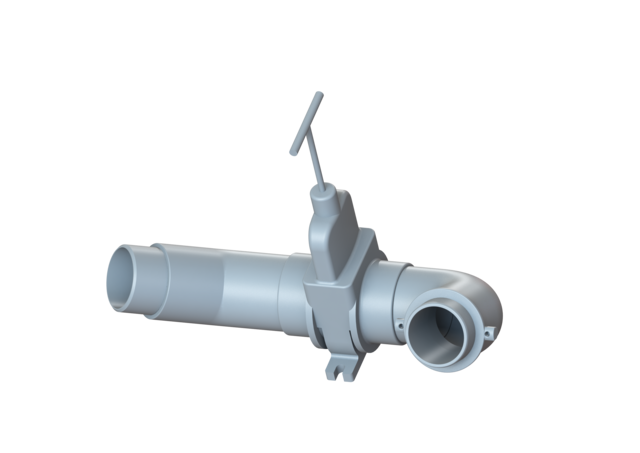

| Pressure pipe with shut-off valve left-hand version, angled | 680401 | Show |

| Pressure pipe with shut-off valve right-hand version, angled | 680402 | Show |

| Support rib for shut-off valve, slanted support | 680403 | Show |

| Seal set Ecolift XL | 680418 | Show |

| Drive motor for clamping on, 10 m cable | 680452 | Show |

| Spare part set, optical probe 10 m cable | 680455 | Show |

| Immersion pipe for Ecolift XL, 180 mm | 680827 | Show |

| Motor-driven backwater flap Premium | 80038 | Show |

| Insert part f. motor-driven flap Premium | 80039 | Show |

| Backwater flap / Insert Premium | 80041 | Show |

| Catalog Page | |

|---|---|

| Manuals | |

| CAD Data | |

| Approval | |

| Test Reports and Certificates | |

| Declaration of Performance | |

| BIM Data |

- Type of wastewater (ATTR-6):

wastewater without sewage

- Number of motor-driven backwater flaps (ATTR-3A): 1

- TÜV test mark (ATTR-376):

ID 1111241794

- Country of origin (ATTR-322): DE

- Area of application (ATTR-264): drainage

- Pump type (ATTR-265): Freestanding pump

- Pump shaft position (ATTR-266): vertical

- Pump design (ATTR-267): Dry rotor pump

- Pump hydraulics (ATTR-268): single stage

- Pump suction characteristic (ATTR-269): non-self-priming

- Pump drive (ATTR-270): E-motor for three-phase current

- E-motor, type of startup (ATTR-271): direct

- Pump casing material (ATTR-272): Grey iron

- Upper tolerance of the operating voltage (+) (ATTR-273): 10 PROZ

- Lower tolerance of the operating voltage (-) (ATTR-274): 10 PROZ

- Upper tolerance of the nominal frequency (+) (ATTR-275): 3 PROZ

- Lower tolerance of the nominal frequency (-) (ATTR-276): 2 PROZ

- Pump electrical connection (ATTR-277): 3/N/PE 400V

- Startup circuit for three-phase connection or three-phase current (ATTR-278): Star

- Motor pump shaft (ATTR-279): continuous

- Shaft seal (ATTR-280): RSSR

- Number of operating pumps (ATTR-281): 1

- Minimum pumped media temperature (ATTR-282): 0 CEL

- Maximum operating pressure (Pmax) (ATTR-283): 800 HPA

- Minimum speed for speed adjustment (ATTR-284): no speed adjustment

- Start-up current (ATTR-285): 21 AMP

- Vertical installation (ATTR-286): yes

- Operating mode, twin systems (ATTR-287): redundant

- Pump (ATTR-4): SPF 1500

- Number of pumps (ATTR-181): 2

- Impeller type (ATTR-8): Multi-vane impeller

- Type of pump connection cable (ATTR-N2): H07RN-F 7G 1.5 mm2

- Type of fuse required (electrical protection) (ATTR-N3): 3 x C 16 A

- Max. permissible switching frequency (ATTR-162): 20 1PH

- Operating mode (ATTR-10): S3 - 50 %

- Power P1 (ATTR-F4): 1.4 KWT

- Power P2 (ATTR-F5): 1.1 KWT

- Speed (ATTR-F2): 1,415 UMIN

- Rated current (ATTR-N5): 2.7 AMP

- Max. pumping capacity (ATTR-F7): 28 MQH

- Max. pumping height (ATTR-F8): 7.5 MTR

- Max. temperature (permanent) of conveyed material (ATTR-132): 40 CEL

- Protection class (ATTR-133): I

- Connection type (ATTR-N1): Direct connection

- Protection class (pump) (ATTR-125): IP 68 (3m/48h)

- Length of mains cable for pump (ATTR-11): 10 MTR

- Temperature monitoring (ATTR-135): integrated

- Weight (ATTR-191): 24 KGM

- Cos phi - power factor (ATTR-192): 0.8

- Insulation class (ATTR-193): F

- Expected service life (hours of operation) (ATTR-194): 5,000 HUR

- Expected service life (number of switching cycles) (ATTR-195): 150,000

- Net weight (ATTR-A3A): 140.4 KGM

- Gross weight (ATTR-A3B): 161.8 KGM

- Installation situation (ATTR-1):

underground installation

- Shut-off valve (ATTR-A1): Shut-off valve made of polymer

- Pressure pipe connection (ATTR-B7): horizontal

- Type of system (ATTR-2): Twin pump station

- Backflow preventer (ATTR-165): integrated

- Pump control (ATTR-134): Control unit

- Note on installation depth (ATTR-188): Version with lowest installation height

- Passage seal for ventilation pipe (DN) (ATTR-183): 70 MMT

- Passage seal for conduit pipe (DN) (ATTR-184): 100 MMT

- Length (ATTR-A6A): 1,245 MMT

- Width (ATTR-A6B): 1,200 MMT

- Height (ATTR-A6C): 780 MMT

- Volume (ATTR-320): 2.5 MTQ

- Packaging dimension: length (ATTR-325): 2,000 MMT

- Packaging dimension: width (ATTR-326): 1,300 MMT

- Packaging dimension: height (ATTR-327): 950 MMT

- Dimensions (ATTR-323): 1300X1300X830/700X800X950MM

- Number of packages (ATTR-321): 2

- Control unit (ATTR-S2):

Comfort Plus

- Self-diagnosis system (SDS) (ATTR-S5): yes

- Battery buffering (ATTR-S6): yes

- Multi-line display (ATTR-S7): yes

- Log book function (ATTR-S8): yes

- USB interface (ATTR-S9): yes

- GSM interface (ATTR-S10): yes

- Potential-free contact (ATTR-S11): yes

- Length of mains cable for control unit (ATTR-S12): 0 MTR

- Operating voltage (ATTR-S13): 400 VLT

- Mains frequency (ATTR-S14): 50 HTZ

- Protection class control unit (ATTR-S4): IP 54

- Alarm sensor (ATTR-S1): optical probe

- Type of level measurement (ATTR-7A): pneumatic

- Level measurement instrument (ATTR-7B): Immersion pipe

- Motor protection switch (ATTR-172): yes

- Clear width of entry (LW) (ATTR-B13): 800 MMT

- Clear width of tank (LW) (ATTR-B14): 1,000 MMT

- Number of inlets (ATTR-B1B): 1 PCE

- Inlet nominal size (DN) (ATTR-B1CA): 150 MMT

- Distance pipe bottom inlet to tank bottom (ATTR-B1D): 135 MMT

- Number of outlets (ATTR-B15B): 1 PCE

- Outlet nominal size (DN) (ATTR-B15CA): 150

- Distance pipe bottom outlet to tank bottom (ATTR-B15D): 120 MMT

- Channel (ATTR-158): continuous channel

- Venting connection (DN) (ATTR-B4): 70 MMT

- Pressure pipe connection (DN) (ATTR-B17): 80 MMT

- Pressure pipe connection (OD) (ATTR-B18): 90 MMT

- Nominal pressure (PN) (ATTR-B18B): 10

- Tank volume (ATTR-B9): 65 LTR

- Pumping volume (ATTR-B10): 20 LTR

- Groundwater resistant from lower edge of base section (ATTR-B12): 3,000 MMT

- Distance from inlet pipe invert to top of tank (ATTR-318): 645 MMT

- Declaration of Performance (DOP) (ATTR-292): 009-033

- Wastewater quantity (ATTR-310):

High

- Protection strategy (ATTR-311):

Central protection

- Position relative to sewer (ATTR-309):

Gradient to the sewer

- Function in the event of backwater (ATTR-312):

Drains in the event of backwater

- Colour (ATTR-102): black

- Note on type of wastewater (ATTR-187): Country-specific regulations related to the area of application can deviate

- Approval (ATTR-A5): Z-53.2-493

- Backwater protection (ATTR-151): Type 3

- Number of mechanical backwater flaps (ATTR-154): 1

- Vertical drop between inlet and outlet (ATTR-176): 15 MMT

- Free passage (ATTR-180): 40 MMT

- Delivery state (ATTR-189): Pre-mounted for final assembly on site (pumps and sensor system must be fitted on site and control unit must be connected)

- Standard (ATTR-9):

- Declaration of conformity (ATTR-289):

yes

- Brand (M-ATTR-001): KESSEL

- Product group (M-ATTR-002): Hybrid lifting stations

- Product type (M-ATTR-003): Backwater lifting station

- Product family (M-ATTR-004): Ecolift

- Product name (M-ATTR-005): Ecolift XL

- Standby power (ATTR-S20): 5 WTT