Grease separator EasyClean free

NS 7, Mix & Pump

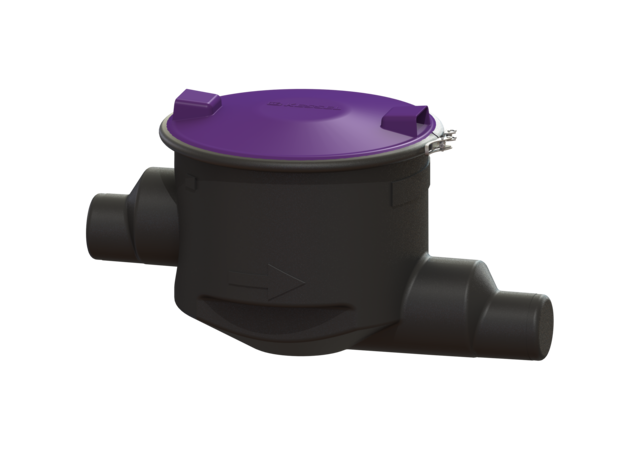

The separator for greasy wastewater is suitable for free-standing set-up in frost-protected rooms and comes without metallic components in the tank. The collecting tank made of permanently resistant polymer (PE) is equipped with an integrated sludge trap and has a tapered base for fast and clean disposal. Two odour-tight covers with quick-release closures make easy access possible for cleaning and maintenance work. The innovative Shredder-Mix-System with integrated macerating system is responsible for homogenising and circulating the tank contents. Cleaning and odour-neutral disposal takes place via an exterior pump with 2-way valve and change lever which can be disconnected from the tank by a shut-off valve. After disposal, a maximum of 3 litres residual sludge volume is left in the tank. Manual control is carried out by a user-friendly control unit that can be integrated into the building management system through a potential-free contact. 20 year polyethylene warranty.

- Direction of flow can be changed thanks to self-sealing interchangeable hubs

- Clean and odour-free disposal and cleaning

- Simple control

| Item no. | 93007.01/MS |

|---|---|

| GTIN | 4026092060940 |

| Price group | 60 |

Grease separator EasyClean free NS 7, Mix & Pump

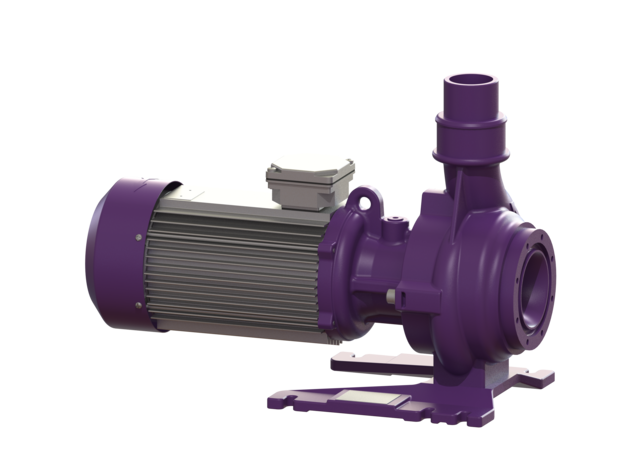

The separator for greasy wastewater is suitable for free-standing set-up in frost-protected rooms and comes without metallic components in the tank. The collecting tank made of permanently resistant polymer (PE) is equipped with an integrated sludge trap and has a tapered base for fast and clean disposal. Two odour-tight covers with quick-release closures make easy access possible for cleaning and maintenance work. The innovative Shredder-Mix-System with integrated macerating system is responsible for homogenising and circulating the tank contents. Cleaning and odour-neutral disposal takes place via an exterior pump with 2-way valve and change lever which can be disconnected from the tank by a shut-off valve. After disposal, a maximum of 3 litres residual sludge volume is left in the tank. Manual control is carried out by a user-friendly control unit that can be integrated into the building management system through a potential-free contact. 20 year polyethylene warranty. Installation situation: free-standing set-up Version: Shut-off valve: yes Type of disposal: manual disposal and cleaning system Disposal system: Disposal pump Disposal variant: Mix & Pump Refill inlet in accordance with DIN 1988: yes Nominal size (NS): 7 Inspection window: yes Shredder-Mix-System: yes SonicControl: no Water supply: 1 screw-type valve 1" Load-bearing capacity (DIN 19901): F3 Delivery state: Installation-ready (electrical components, connection parts must be connected on site) Scope of delivery: Storz-B coupling R 2 1/2" for disposal vehicle connection General characteristics: Material: PE Standard: EN 1825: 2004, DIN 4040-100 Dimensions: Set-up area, length: 2,147 mm Set-up area, width: 1,108 mm Set-up area, height: 1,892 mm Required access area, length: 1,910 mm Required access area, width: 940 mm Required access area, height: 1,678 mm Tank: Inlet nominal size (DN): 150 Inlet nominal size (OD): 160 mm Outlet nominal size (DN): 150 Outlet nominal size (OD): 160 mm Distance pipe bottom inlet to tank bottom: 1,255 mm Distance pipe bottom outlet to tank bottom: 1,185 mm Pressure pipe connection (DN): 65 mm Pressure pipe connection (OD): 75 mm Nominal pressure (PN): 10 Connection inlet/outlet sockets: PE-HD pipes in accordance with DIN 19537, HT pipes in accordance with DIN 19560, PP or AS Coverage features: Type of cover: Cover Cover material: Polymer Colour of cover: violet Tightness: odour-tight Locking: Quick-release closure Wastewater contents: Separator contents: 650 l Total volume: 1,350 l Contents of sludge trap: 700 l Storage quantity of grease: 280 l Pumping device: Pump: SPF 300 KE 2.0 Number of pumps: 1 Max. pumping capacity: 60 m3/h Max. pumping height: 17 m Operating voltage: 400 V Mains frequency: 50 Hz Operating mode: S2 - 30 min. Power P1: 3.6 kW Power P2: 3 kW Speed: 2,850 U/min Type of fuse required (electrical protection): Fuse protection through control unit 400 V Max. temperature (permanent) of conveyed material: 40 °C Connection type: Direct connection Weight: 44 kg Impeller type: Radial impeller with macerating system Length of mains cable for pump: 5 m Rated current: 6.2 A Protection class (pump): IP 55 Protection class: I Type of pump connection cable: H07RN-F 7G 1.5 mm2 Temperature monitoring: integrated Cos phi - power factor: 0.87 Insulation class: F Control: Control unit: yes Operating voltage: 400 V Mains frequency: 50 Hz Self-diagnosis system (SDS): yes Battery buffering: no Multi-line display: no Log book function: no USB interface: no GSM interface: no Potential-free contact: yes Type of fuse required (electrical protection): 3 x C 16 A Type of fuse required (RCD): 30 mA Motor protection switch: yes Protection class control unit: IP 54

Video

Installation Video

| Title | Item no. |

|---|

| Title | Item no. |

|---|

| Title | Item no. | ||

|---|---|---|---|

| Sampling system DN 100/150, Vertical outlet | 915870 | Show |

| Sampling system DN 100/150, Horizontal outlet | 915871 | Show |

| Access panel for mounting on-wall | 917413 | Show |

| Access panel for in-wall installation | 917414 | Show |

| 'SonicControl' level sensing system | 917821 | Show |

| Cable extension 10 m, for SonicControl grease separator | 917871 | Show |

| Cable extension 20 m, for SonicControl grease separator | 917872 | Show |

| Cable extension 30 m, for SonicControl grease separator | 917873 | Show |

| Title | Item no. | ||

|---|---|---|---|

| Seal DN 150 | 680003 | Show |

| Hose clamp d: 110 mm | 680126 | Show |

| Seal DN 200 | 680128 | Show |

| Screw 10x3, A2 | 680164 | Show |

| Valve 2-way redistributor, with lever | 680274 | Show |

| Shut-off valve DN 100, polymer, horizontal | 680329 | Show |

| Control unit Mix & Pump, 6.5, 7.5 and 10 A | 680341 | Show |

| Flexible coupling DN 100, L: 100 mm | 680434 | Show |

| Inlet socket for grease separator NS 7-10 | 680436 | Show |

| Outlet socket for grease separator NS 7-10 | 680438 | Show |

| Inlet/outlet structure for grease separator NS 2-10 | 680439 | Show |

| Flexible coupling with hose clamps, DN 75, L: 100 mm | 680555 | Show |

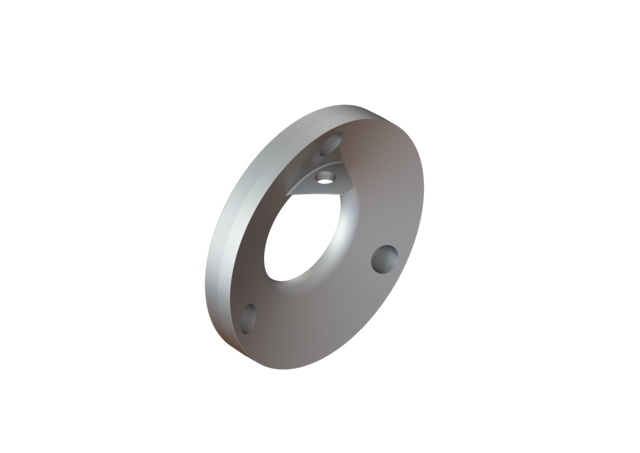

| Adapter for pump, Euro grease separator | 680590 | Show |

| EasyClean Inspection Window | 913109 | Show |

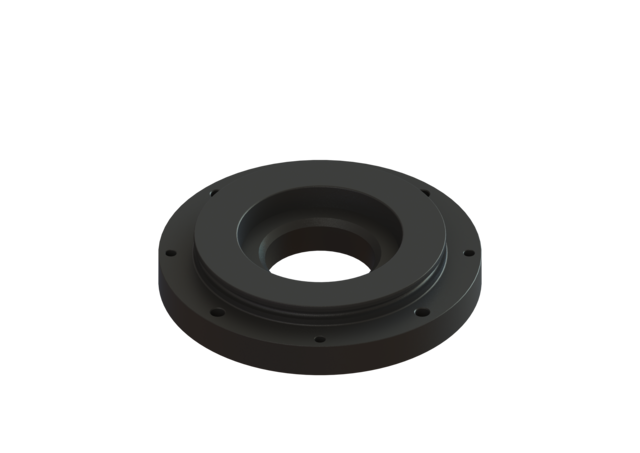

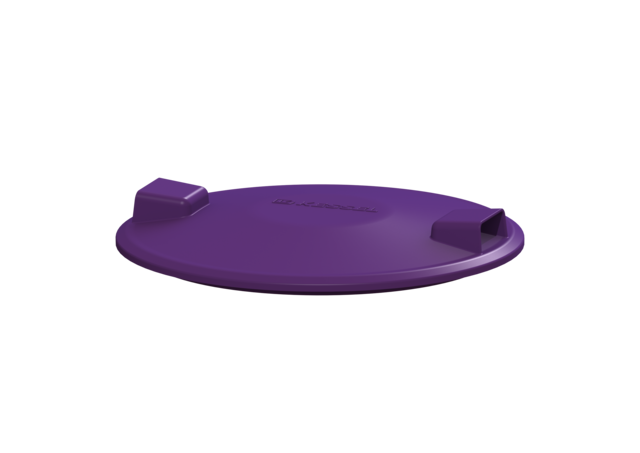

| Cover for Euro separator 420mm | 916904 | Show |

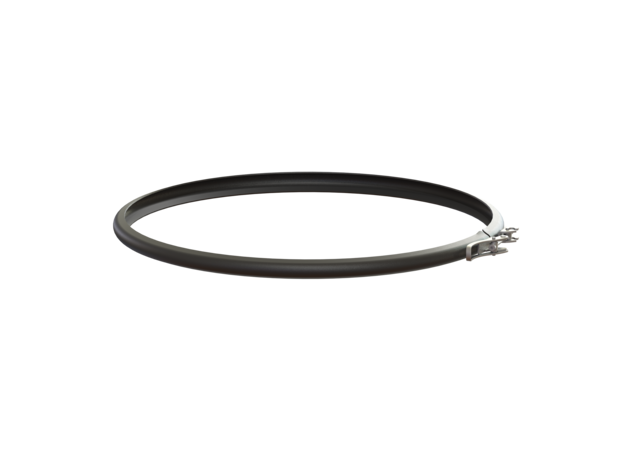

| Quick release clamp420mm | 917004 | Show |

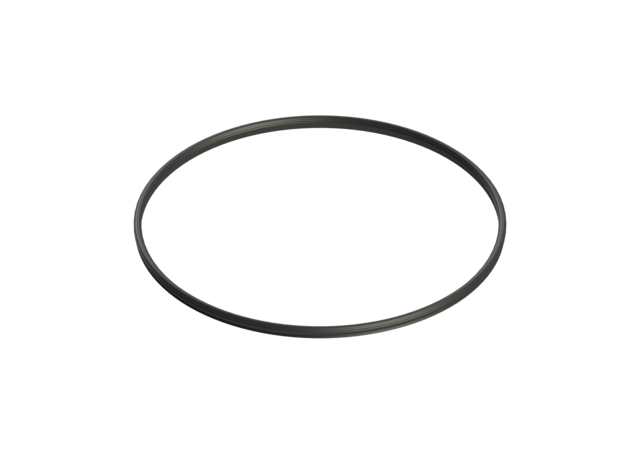

| Gasket for separator cover 420mm | 917204 | Show |

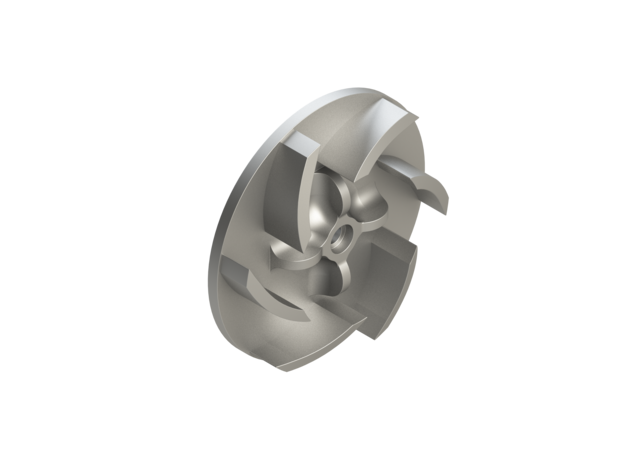

| Impeller | 917854 | Show |

| Cutting Plate for 3,0 kW Pump | 917855 | Show |

| 3,0 kw Pump | 917856 | Show |

| Catalog Page | |

|---|---|

| Manuals | |

| CAD Data | |

| Declaration of Performance | |

| Declaration of Conformity |

- External monitoring (ATTR-A8):

- Country of origin (ATTR-322): DE

- Gross weight (ATTR-A3B): 240 KGM

- Net weight (ATTR-A3A): 210 KGM

- Storage quantity of grease (ATTR-208): 280 LTR

- Total volume (ATTR-209): 1,350 LTR

- Set-up area, length (ATTR-A7A): 2,147 MMT

- Set-up area, width (ATTR-A7B): 1,108 MMT

- Set-up area, height (ATTR-A7C): 1,892 MMT

- Required access area, length (ATTR-217): 1,910 MMT

- Required access area, width (ATTR-218): 940 MMT

- Required access area, height (ATTR-219): 1,678 MMT

- Volume (ATTR-320): 4.3 MTQ

- Packaging dimension: length (ATTR-325): 2,200 MMT

- Packaging dimension: width (ATTR-326): 1,150 MMT

- Packaging dimension: height (ATTR-327): 1,700 MMT

- Dimensions (ATTR-323): 2200X1150X1800MM

- Number of packages (ATTR-321): 1

- Shut-off valve (ATTR-A1): yes

- Nominal size (NS) (ATTR-197): 7

- Disposal variant (ATTR-198): Mix & Pump

- Type of disposal (ATTR-199): manual disposal and cleaning system

- SonicControl (ATTR-202): no

- Inspection window (ATTR-203): yes

- Refill inlet in accordance with DIN 1988 (ATTR-204): yes

- Water supply (ATTR-235): 1 screw-type valve 1"

- Load-bearing capacity (DIN 19901) (ATTR-305): F3

- Contents of sludge trap (ATTR-206): 700 LTR

- Separator contents (ATTR-207): 650 LTR

- Pump (ATTR-4): SPF 300 KE 2.0

- Number of pumps (ATTR-181): 1

- Impeller type (ATTR-8): Radial impeller with macerating system

- Type of pump connection cable (ATTR-N2): H07RN-F 7G 1.5 mm2

- Type of fuse required (electrical protection) (ATTR-N3): Fuse protection through control unit 400 V

- Max. permissible switching frequency (ATTR-162): 20 1PH

- Operating mode (ATTR-10): S2 - 30 min.

- Power P1 (ATTR-F4): 3.6 KWT

- Power P2 (ATTR-F5): 3 KWT

- Speed (ATTR-F2): 2,850 UMIN

- Operating voltage (ATTR-131): 400 VLT

- Mains frequency (ATTR-N4): 50 HTZ

- Rated current (ATTR-N5): 6.2 AMP

- Max. pumping capacity (ATTR-F7): 60 MQH

- Max. pumping height (ATTR-F8): 17 MTR

- Max. temperature (permanent) of conveyed material (ATTR-132): 40 CEL

- Protection class (ATTR-133): I

- Connection type (ATTR-N1): Direct connection

- Protection class (pump) (ATTR-125): IP 55

- Length of mains cable for pump (ATTR-11): 5 MTR

- Temperature monitoring (ATTR-135): integrated

- Weight (ATTR-191): 44 KGM

- Cos phi - power factor (ATTR-192): 0.9

- Insulation class (ATTR-193): F

- Expected service life (hours of operation) (ATTR-194): 5,000 HUR

- Expected service life (number of switching cycles) (ATTR-195): 150,000

- Connection inlet/outlet sockets (ATTR-B14B): PE-HD pipes in accordance with DIN 19537, HT pipes in accordance with DIN 19560, PP or AS

- Inlet nominal size (DN) (ATTR-B1CA): 150 MMT

- Inlet nominal size (OD) (ATTR-B1CB): 160 MMT

- Distance pipe bottom inlet to tank bottom (ATTR-B1D): 1,255 MMT

- Outlet nominal size (DN) (ATTR-B15CA): 150

- Outlet nominal size (OD) (ATTR-B15CB): 160

- Distance pipe bottom outlet to tank bottom (ATTR-B15D): 1,185 MMT

- Pressure pipe connection (DN) (ATTR-B17): 65 MMT

- Pressure pipe connection (OD) (ATTR-B18): 75 MMT

- Nominal pressure (PN) (ATTR-B18B): 10

- Self-diagnosis system (SDS) (ATTR-S5): yes

- Battery buffering (ATTR-S6): no

- Multi-line display (ATTR-S7): no

- Log book function (ATTR-S8): no

- USB interface (ATTR-S9): no

- GSM interface (ATTR-S10): no

- Potential-free contact (ATTR-S11): yes

- Operating voltage (ATTR-S13): 400 VLT

- Mains frequency (ATTR-S14): 50 HTZ

- Protection class control unit (ATTR-S4): IP 54

- Type of fuse required (electrical protection) (ATTR-S17): 3 x C 16 A

- Type of fuse required (RCD) (ATTR-S18): 30 MAMP

- Motor protection switch (ATTR-172): yes

- Type of cover (ATTR-A21): Cover

- Colour of cover (ATTR-A2A): violet

- Tightness (ATTR-A2C): odour-tight

- Locking (ATTR-A2D): Quick-release closure

- Cover material (ATTR-A2E):

Polymer

- Diameter (ATTR-A107): 420 MMT

- Standard (ATTR-9): EN 1825: 2004

- CE marking (ATTR-A5B):

yes

- Scope of delivery (ATTR-234): Storz-B coupling R 2 1/2" for disposal vehicle connection

- 4MS common composition list (ATTR-291): Requirements fulfilled

- Declaration of Performance (DOP) (ATTR-292): 009-017

- Control unit (ATTR-S2):

yes

- Disposal system (ATTR-200):

Disposal pump

- Shredder-Mix-System (ATTR-201):

yes

- Installation situation (ATTR-1):

free-standing set-up

- Material (ATTR-101):

PE

- Delivery state (ATTR-189): Installation-ready (electrical components, connection parts must be connected on site)

- Reaction to fire (ATTR-306): Class E to EN 13501-1

- Notified test body (ATTR-307): nb0979

- Year of initial approval (ATTR-308): 2,015

- Declaration of conformity (ATTR-303): 009-017-C

- Brand (M-ATTR-001): KESSEL

- Product group (M-ATTR-002): Separator technology

- Product type (M-ATTR-003): Grease separator

- Product family (M-ATTR-004): EasyClean

- Product name (M-ATTR-005): EasyClean free